Case Study - E-Liquid Manufacturer

Customer Profile

Our client is one of the EU’s foremost manufacturers and distributors of e-liquids for vaping devices, specializing in e-liquid flavor development, bottling, brand design, and distribution. Their focus is bringing innovative consumer products to the market. They manufacture nicotine, nicotine-free, nicotine salts vape products as well as personal care and CBD products

The Customer’s Requirements

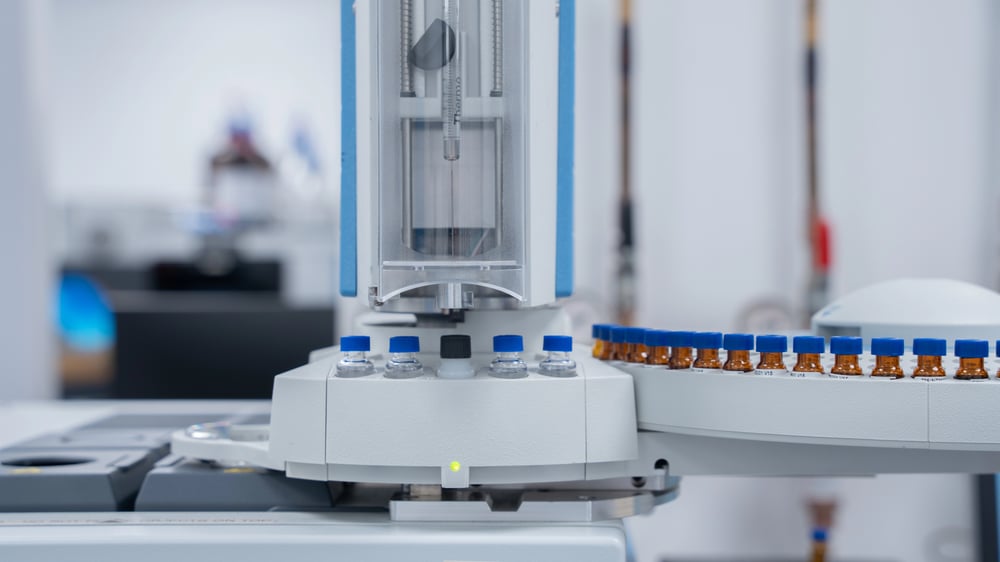

The client was looking to bring the filling of vape devices in-house, after previously outsourcing it to overseas manufacturers. When launching this new in-house process, they asked us to provide independent testing of their products to ensure they complied with regulatory requirements. We supported with analytical testing of their initial vape product batches using the new in-house filling process to verify the calibration and setup of the new machinery.

Our Service Offering

We supported the manufacturer in bringing their e-liquid filling process in-house by testing fill volume on their first batches of prototype products. Our experience in vape analytical testing and the manufacturing processes helped to support the manufacturer to ensure their new in-house processes were correctly calibrated and the products produced complied with regulations.

Why Broughton

- Our well-established reputation for helping clients bring new vape products to market was a key factor in the manufacturer choosing us as a partner.

- Our UKAS-accredited laboratory facilities and our testing processes being governed by a Quality Management System accredited to ISO 17025:2017 gave the client confidence.

- The ability to deliver a quick turnaround on the project to support the client’s new strategic business direction was also essential.

Project Deliverables

Our team helped the client set up and calibrate the new machinery, allowing them to produce products that were compliant with the relevant regulatory requirements and enabling them to launch the new filling process and bring manufacturing in-house. The project required the use of our accredited test methods to deliver high-quality analytical data to the client, providing them with the information they needed to gain complete confidence in implementing this major manufacturing change.

Learn More About Our Nicotine Services

Nicotine Services

We support our partners in accelerating next generation nicotine delivery products to market within their chosen regulatory framework to help make tobacco harm reduction a reality around the world and contribute to a smoke free future. Learn more about our Nicotine Services here.